Optimization of cultivation conditions for the production of phytate-degrading enzymes by Enterobacter sakazakii ASUIA279 isolated from Malaysian maize root

DOI:

https://doi.org/10.20873/jbb.uft.cemaf.v3n2.hussinPalabras clave:

bacterial phytase, statistical optimization, cultivation conditionsResumen

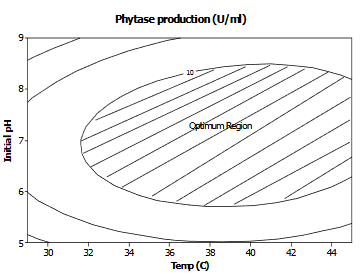

The production of extracellular phytase by Enterobacter sakazakii ASUIA279 was optimized using response surface methodology with full-factorial faced centred central composite design. Two sets of experiments were carried out to optimize the five most profound factors of the cultivation conditions in order to maximize phytase production. Incubation temperature, initial pH of the media and percentage of rice bran supplemented into the media were optimized in Erlenmeyer flasks while agitation and aeration effect were controlled in a bioreactor. This design reduced the number of actual experiment performed to optimize phytase production and allowed the study of possible interactions among the factors. In the first set of experiments linear and quadratic effect of initial pH was determined to be the most significant factor affecting phytase production. In the bioreactor both linear effects of agitation and aeration, were identified to be highly significant (> 99 %) in respect to phytase yields. Optimal phytase production was observed at a incubation temperature of 39.7 ºC, an initial pH of 7.1, supplementation with 13.6 % rice bran , 320 rpm of agitation and 0 vvm of aeration.

Citas

Akhnazarova, S. and Kefarov, V. (1982), Experiment optimization in chemistry and chemical engineering. Moscow: Mir Publisher.

Anis Shobirin, M. H. (2008), Development of bioprocessing technique for the production and purification of phytate-degrading enzyme from Malaysian soil bacteria. PhD Thesis Dissertation. IIUM.

Beg, Q. K.; Saxena, R. K.; Gupta, R. (2002), Kinetic constants determination for an alkaline protease from Bacillus mojavensis using response surface methodology. Biotechnology Bioengineering, 78, 289-295.

Beg, Q. K.; Sahai, V.; Gupta, R. (2003), Statistical optimization and alkaline protease production from Bacillus mojavensis in a bioreactor. Proceeding Biochemistry, 39, 203-209.

Berka, R. M.; Rey, M. W.; Brown, K. M.; Byun, T.; Klotz, A. V. (1998), Molecular characterization and expression of a phytase gene from the thermophilic fungus Thermomyces lanuginosus. Applied Environmental Microbiology, 64, 4423-4427.

Bogar, B.; Szakacs, G.; Linden, J. C.; Pandey, A.; Tengerdy, R. B. (2003), Optimization of phytase production by solid substrate fermentation. Journal of Industrial Microbiology and Biotechnology, 30, 183-189.

Choi, Y. M.; Dong, O. N.; Cho, S. H.; Lee, H. K.; Suh, H. J.; Chung, S. H. (1999), Isolation of a phytase producing Bacillus sp. KHU-10 and its phytase production. Microbiology Biotechnology, 9, 223-226.

De Cornink, J.; Bouquelet, S.; Dumortier, V.; Duyme, F.; Denantes, V. I. (2000), Industrial media and fermentation process for improved growth and protease production by Tehrahymena thermophila BIII. Indian Microbiology Biotechnology, 24, 285-290.

Gautam, P.; Sabu, A.; Pandey, A.; Szakacs, G.; Soccol, C. (2002), Microbial production of extra- cellular phytase using polysterene as inert solid support. Bioresource Technology, 83, 229-233.

Greiner, R.; Konitzny, U.; Jany, K. D. (1993), Purification and characterization of two phytases from Escherichia coli. Achieves Biochemistry Biophysical, 303, 107-113.

Greiner, R.; Haller, E.; Konietzky, U.; Jany, K. D. (1997), Purification and characterization of a phytase from Klebsiella terrigena. Achieves Biochemistry Biophysical, 341, 201-206.

Heinonen, J. K. and Lahti, R. J. (1981), A new and convenient colorimetric determination of inorganic orthophosphate and its application to the assay of inorganic pyrophosphatase. Analysis Biochemistry, 113, 313-317.

Irving, G. C. J. and Cosgrove, D. J. (1971), Inositol phosphate phosphatases of microbiological origin. Some properties of partially purified bacterial (Pseudomonas sp.) phytase. Australian Journal Biological Science, 24, 547-557.

Irving, G. C. J. and Cosgrove, D. J. (1972), Inositol phosphate phophatase of microbiological origin: the inositol pentaphosphate products of Aspergillus ficuum phytase. Journal Bacteriology, 112, 434-438.

Karthikeyan, R. S.; Rakshit, S. K.; Baradarajan, A. (1996), Optimization of batch fermentation conditions for dextran production. Bioprocess Engineering, 15, 247-251.

Khuri, A. I. and Cornell, J. A. (1987), Response surfaces: design and analysis. New York: John Wiley and Sons, 291-334.

Kim, Y. O.; Kim, H. K.; Bae, K. S.; Yu, J. H.; Oh, T. K. (1998), Cloning of thermostable phytase gene (phy) from Bacillus sp. DS11 and its overexpression in Escherichia coli. FEMS Microbiology Letters, 162, 185-191.

Krishna, C. and Nokes, S. E. (2001), Predicting vegetative inoculum performance to maximize phytase production in solid-state fermentation using response surface methodology. Indian Microbiology Biotechnology, 26,161-170.

Mitchell, D. B.; Vogel, K.; Weimann, B. J.; Pasamontes, L.; Van Loon, A. S. P. G. M. (1997), The phytase subfamily of histidine acid phosphatases: isolation of gene for two novel phytases from the fungi Aspergillus tereus and Myceliophthora thermophila. Microbiology, 143, 245-252.

Muralidhar, R. V.; Chirumamila, R. R.; Marchant, R.; Nigam, P. (2001), A response surface approach for the comparison of lipase production by Candida cylindracea using two different carbon sources. Biochemistry Engineering, 9, 17-23.

Nagashima, T.; Tange, T.; Anazawa, H. (1999), Dephosphorylation of phytase by using the Aspergillus niger phytase with a high affinity for phytate. Applied Environmental Microbiology, 65, 4682-4684.

Park, K. M. and Reardon, K. F. (1996), Medium optimization for recombinant protein production by Bacillus subtilis. Biotechnology Letters, 18, 737-740.

Pasamontes, L.; Haiker, M.; Wyss, M.; Tessier, M..; Van Loon A. P. G. M., (1997), Gene cloning, purification, and characterization of a heat-stable phytase from the fungus Aspergillus fumigatus. Applied Environmental Microbiology, 63, 1696-1700.

Poulsen, H. D. (2000), Phosphorus utilization and excretion in pig production. Journal Environmental Quality, 29, 24-27.

Powar, V. K. and Joganathan, V. (1982), Purification and properties of phytate specific phosphatase from Bacillus subtilis. Journal Bacteriology, 151, 1102-1108.

Puri, S.; Beg, Q. K.; Gupta, R. (2002), Optimization of alkaline protease production from Bacillus sp. using response surface methodology. Current Microbiology, 44, 286-290.

Quan, C.; Zhang, L.; Wang, Y.; Ohta Y. (2001), Production of phytase in a low phosphate medium by a novel yeast Candida krusei. Journal Bioscience Bioengineering, 92 154-160.

Segueilha, L.; Lambrechts, C.; Boze, H.; Moulin, G.; Galzy, P. (1992), Purification and properties of the phytase from Schwanniomyces castellii. Fermentation Bioengineering, 74, 7-11.

Shieh, T. R. and War,e J. H. (1968), Survey of microorganisms for the production of extracellular phytase. Applied Microbiology, 16, 1348-1351.

Vohra, A. and Satyanarayana, T. (2003), Phytases: Microbial sources, production, purification, and potential biotechnological applications. Critical Review Biotechnology, 23, 29-60.

Wodzinski, R. J. and Ullah, A. M. J. (1996), Phytase. Advance Applied Microbiology, 42, 263-302.

Yamada, K.; Minoda, Y.; Yamamoto, S. (1968), Phytase from Aspergillus terreus 1. Production, purification and some general properties of the enzyme. Agriculture Biology Chemistry, 32, 1275-1282.

Yanke, L. J.; Bae, H. D., Selinger, L. B.; Cheng, K. J. (1998), Phytase activity of anaerobic ruminal bacteria. Microbiology, 144, 1565-1573.

Descargas

Publicado

Cómo citar

Número

Sección

Licencia

Copyright (c) 2024 - Journal of Biotechnology and Biodiversity

Esta obra está bajo una Licencia Creative Commons Atribución 4.0 Internacional.

Los autores que publican en esta revista aceptan los siguientes términos:

Los autores mantienen los derechos autorales y conceden a la revista el derecho de primera publicación, con el trabajo simultáneamente licenciado bajo la LicenciaCreative Commons Attribution (CC BY 4.0 en el link http://creativecommons.org/licenses/by/4.0/) que permite compartir el trabajo con reconocimiento de la autoría y publicación inicial en esta revista.

Los autores tienen autorización para asumir contratos adicionales separadamente, para distribución no exclusiva de la versión del trabajo publicado en esta revista (ej.: publicar en repositorio institucional o como capítulo de libro), con reconocimiento de autoría y publicación inicial en esta revista.

A los autores se les permite, y son estimulados, a publicar y distribuir su trabajo online (ej.: en repositorios institucionales o en su página personal) en cualquier punto antes o durante el proceso editorial, ya que esto puede generar alteraciones productivas, bien como aumentar el impacto y la citación del trabajo publicado (disponible en El Efecto del Acceso Libre en el link http://opcit.eprints.org/oacitation-biblio.html).